You have a game-changing idea for a supplement brand. You see a gap in the market, you know your audience, and you’re ready to build a community. But there’s a major hurdle standing in your way: turning that brilliant concept into a physical product. The world of manufacturing, formulation, sourcing, and regulations can feel overwhelming, expensive, and incredibly complex.

What if there was a faster, more efficient, and less risky way to bring your product to life?

This is where an ODM supplement factory becomes your most valuable partner. This model is the launchpad for thousands of successful brands, from agile startups to established market leaders. It’s a strategic shortcut that allows you to focus on what you do best—building your brand—while experts handle the entire production lifecycle. This guide will walk you through everything you need to know, providing a clear, end-to-end roadmap from initial idea to market-ready product.

What is an ODM Supplement Factory? (And How It Differs from OEM)

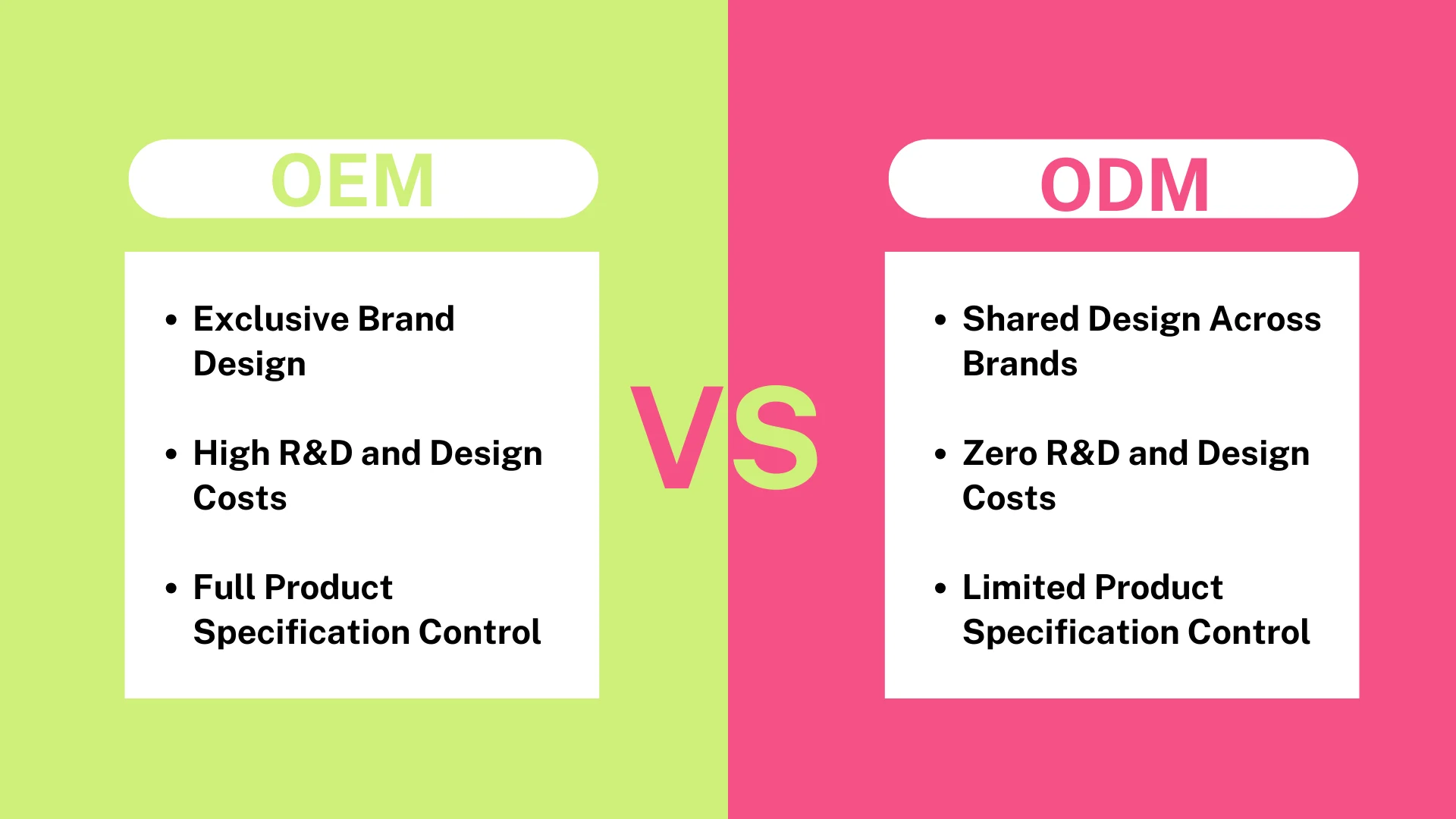

Understanding the manufacturing landscape starts with knowing the key players. While you may hear terms like OEM and ODM used interchangeably, they represent two distinct partnership models. Choosing the right one is critical to your brand’s success.

Defining ODM: Your All-in-One Product Development Partner

ODM stands for Original Design Manufacturing. An ODM partner is a factory that has already done the heavy lifting of research and development. They have a portfolio of market-tested, ready-to-go product formulations that you can select, modify slightly (e.g., flavor, color), and brand as your own.

Think of it as a turnkey supplement manufacturing solution. The ODM factory provides the foundational formula, sources the raw materials, manufactures the product, and handles quality control. You bring your brand, your vision, and your marketing prowess. This synergy allows for an incredibly fast and efficient path to market.

ODM vs. OEM: Choosing the Right Model for Your Brand

OEM, or Original Equipment Manufacturing, is a different approach. In an OEM model, you (the brand) are responsible for providing a complete, detailed product design and formulation to the factory. The factory’s job is simply to manufacture the product according to your exact specifications.

Here’s a clear breakdown to help you decide which model is right for you:

| Feature | ODM (Original Design Manufacturing) | OEM (Original Equipment Manufacturing) |

|---|---|---|

| Product Idea | Factory provides a base formula for you to choose from. | You provide the complete, custom formula and design. |

| R&D Investment | Minimal; handled by the factory. | Significant; handled entirely by you. |

| Intellectual Property | The base formula is owned by the factory. | The formula and design are owned by you. |

| Speed-to-Market | Fast. Weeks to a few months. | Slow. Many months to over a year. |

| Upfront Cost | Lower. No R&D or tooling costs. | Higher. Requires investment in formulation and testing. |

| Best For | Startups, e-commerce sellers, and brands wanting to quickly test or expand product lines. | Established brands with in-house R&D teams and unique, proprietary formulas. |

For most new and growing brands, the ODM model is the clear winner for its balance of speed, cost-effectiveness, and quality.

Why Choose the ODM Model? 7 Key Benefits for Your Supplement Brand

Opting for an ODM partner isn’t just about convenience; it’s a powerful strategic decision that gives your brand a significant competitive edge. Here are the core benefits you can expect.

- Accelerated Speed-to-Market With pre-developed and stability-tested formulas, you can bypass months—or even years—of R&D. This allows you to capitalize on market trends quickly and get your product in front of customers faster than the competition.

- Reduced R&D Costs & Risks Custom supplement formulation is expensive and fraught with risk. An ODM partnership eliminates these upfront costs and the uncertainty of whether a new formula will be effective or stable. You leverage the factory’s proven investment.

- Access to Proven Formulations Top ODM factories invest heavily in creating effective, in-demand products. You gain immediate access to a library of formulas that are already validated for efficacy and popularity, increasing your chances of commercial success.

- Expertise & Industry Knowledge You’re not just buying a product; you’re gaining a partner with deep industry expertise. They understand regulatory hurdles, sourcing challenges, and manufacturing best practices, helping you avoid costly mistakes.

- Simplified Supply Chain An ODM partner manages the entire supply chain, from sourcing high-quality raw ingredients to final packaging. This streamlines your operations and frees you from the logistical nightmare of coordinating multiple vendors.

- Guaranteed Quality Control & Compliance A reputable ODM supplement factory will already be operating under strict quality standards. They handle the complexities of GMP (Good Manufacturing Practices) certification and other regulatory requirements, ensuring your product is safe, consistent, and legal.

- Focus on Your Core Business By outsourcing production, you can dedicate 100% of your time and resources to branding, marketing, and customer relationships—the activities that truly grow your business.

The End-to-End ODM Process: A 6-Step Journey from Idea to Market

The path from concept to finished product is remarkably straightforward with the right ODM partner. While specifics may vary, the journey generally follows these six key steps.

- Step 1: Consultation & Idea Refinement It all begins with a conversation. You’ll discuss your brand vision, target audience, and product goals with the ODM’s experts. They will help you navigate their portfolio of base formulas to find the perfect match for your needs.

- Step 2: Formula Selection & Customization You’ll select a base formula from the ODM’s catalog. This is also the stage for minor customizations. You might choose a specific flavor, select a natural sweetener, or decide on the color of your capsules.

- Step 3: Sourcing & Raw Material Testing Once the formula is finalized, the factory leverages its trusted supplier network to source high-quality raw ingredients. Every ingredient undergoes rigorous testing to verify its identity, purity, and potency before it ever enters the production line.

- Step 4: Manufacturing & Quality Assurance The product is manufactured in a GMP-certified facility. Throughout the process, multiple quality checks are performed—from blending and encapsulation to final product inspection—to ensure every batch meets the exact specifications.

- Step 5: Packaging, Labeling & Design While the product is being made, you’ll work on your branding. Many ODM partners offer in-house design and packaging services. You’ll provide your logo and brand guidelines, and they will help create compliant, eye-catching labels and packaging solutions.

- Step 6: Final Delivery & Logistics After a final round of quality control and third-party testing (if requested), your finished, packaged, and market-ready product is shipped to your warehouse or fulfillment center.

How to Choose the Right ODM Supplement Factory: A Checklist

Selecting your manufacturing partner is one of the most important decisions you’ll make. Not all factories are created equal. Use this checklist to vet potential partners and ensure you find a reliable, high-quality manufacturer.

Essential Certifications: Non-Negotiable Quality Standards

Certifications are your proof of quality and safety. At a minimum, look for:

- GMP (Good Manufacturing Practices): This is the gold standard. A cGMP-certified facility adheres to the FDA’s strictest requirements for manufacturing, processing, and packaging. Do not compromise on this.

- FDA Registered Facility: Ensures the factory is registered with the U.S. Food and Drug Administration and is subject to their inspection.

- Third-Party Certifications (NSF, ISO): Certifications from organizations like NSF International or ISO provide an extra layer of assurance that the factory meets high standards for quality, safety, and operational excellence.

Production Capabilities & Specializations

Does the factory have the technology and expertise to produce the specific product you want?

- Dosage Forms: Can they produce capsules, tablets, powders, liquids, softgels, or trendy forms like vitamin gummies?

- Niche Expertise: Do they specialize in a certain category, like sports nutrition, herbal supplements, or nootropics? A specialist often has deeper formulation knowledge.

Minimum Order Quantity (MOQ) and Scalability

This is a critical factor, especially for startups.

- Low MOQ: A low MOQ supplement manufacturer is ideal for new brands, allowing you to launch with less upfront investment and risk. Ask directly: “What is your MOQ for this product?”

- Scalability: Can they grow with you? Ensure they have the capacity to handle much larger orders as your brand succeeds.

Transparency and Communication

A good partner operates with transparency. They should be willing to discuss their sourcing practices, quality control procedures, and pricing structure openly. Responsive and clear communication is a strong indicator of a healthy partnership.

R&D Strength and Ingredient Sourcing

Even in an ODM model, the factory’s R&D team is a valuable asset. A strong team indicates a commitment to innovation and quality. Ask about their ingredient sourcing policy—do they have a global network of vetted suppliers? Do they prioritize clean, traceable ingredients?

Key Questions to Ask a Potential ODM Partner

Before you sign any contract, have a detailed conversation with your potential partner. Here are some essential questions to ask:

- About Your Process: “Can you walk me through your entire ODM process, from initial quote to final delivery?”

- About Quality: “What are your specific quality control checkpoints? Can you provide a Certificate of Analysis (COA) for every batch?”

- About Sourcing: “Where do you source your primary ingredients from? How do you vet your suppliers?”

- About Cost: “What is included in your per-unit quote? Are there separate fees for setup, packaging, or lab testing?”

- About Support: “What level of support do you provide for label design and FDA compliance?”

- About Lead Time: “What is your typical lead time for a first order and for reorders?”

Frequently Asked Questions (FAQ)

1. How much does it cost to start a supplement line with an ODM? The cost varies widely based on the formula’s complexity, ingredient costs, and order quantity. However, the ODM model significantly lowers the barrier to entry. By avoiding R&D costs, your primary expenses are inventory and packaging, which could range from a few thousand to tens of thousands of dollars.

2. How long does the ODM process take? One of the biggest advantages of ODM is speed. From finalizing your formula to receiving your finished product, the process can take as little as 8-12 weeks, compared to 12-18 months for a custom OEM project.

3. Who owns the final product formula in an ODM model? The base formula’s intellectual property remains with the ODM factory. However, your branding, logo, and any unique combination of flavor/color are exclusively yours. This arrangement is what allows for the cost and time savings.

4. Can you help with packaging design? Yes, most top-tier supplement contract manufacturing partners offer comprehensive packaging and labeling services. They can help you source bottles, jars, or pouches and provide design support to ensure your label is not only attractive but also fully compliant with FDA regulations.

Ready to Launch Your Brand? Let’s Build It Together.

Choosing the right manufacturing model is the foundation of a successful supplement brand. The ODM path offers an unparalleled combination of speed, efficiency, and expert guidance, empowering you to compete in a dynamic market without the prohibitive costs and risks of starting from scratch. By partnering with an experienced and certified ODM supplement factory, you can transform your vision into a high-quality, market-ready product with confidence.

As a GMP-certified leader in private label supplements, we specialize in helping brands of all sizes navigate this journey. With a vast portfolio of innovative formulas, flexible MOQs for startups, and a dedicated team of experts, we are more than a manufacturer—we are your strategic partner in growth.

If you’re ready to take the next step, contact our team today for a free consultation. Let’s discuss your vision and build your brand together.